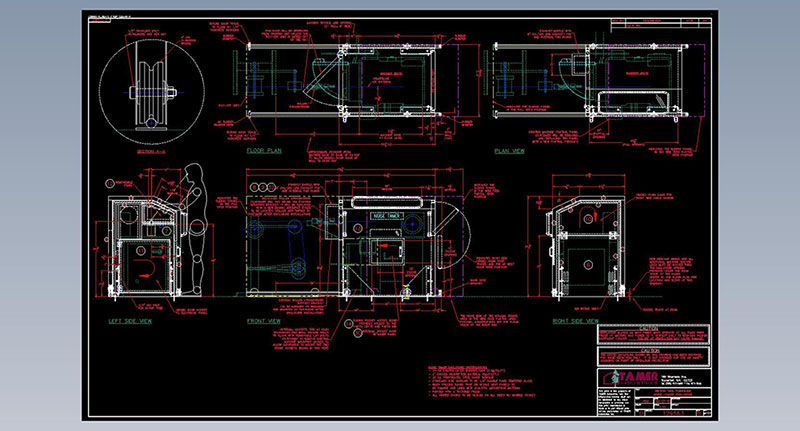

Nilson 700 Fourslide Machine

The Problem

Shop floor containing multiple fourslide machines create excessive noise

Solution

Noise-Tamer custom acoustic enclosure system with sliding

cover and hinged access doors- talk about the difference in noise reduction…

Enclosure Specifications

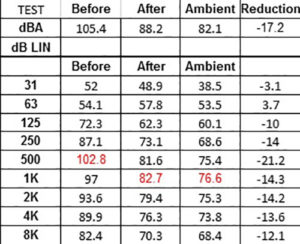

- 2″ acoustic wall thickness

- 14 GA damped outer barrier/skin (2.5#/sq.ft.)

- 2”-6#/cu.ft. mineral wool (bagged) lining

- 22 gauge perforated steel inner surface

- 1/4″ double pane tempered glass

- Hinged doors sealed on all sides with a bubble gasket

Overview of Benefits

- Substantial noise reduction

- Front, rear and overhead access when the sliding cover is open

- Easy access through removable panels

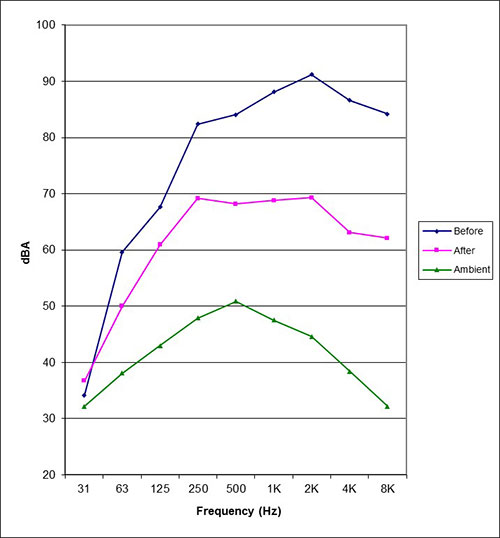

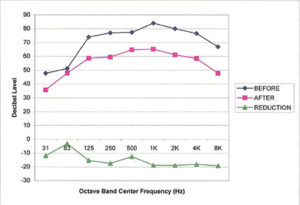

Results – Evaluation

The starting noise level was measured at 95.1 dBA. Upon completion

of the Noise-Tamer enclosure installation the operating noise levels

were measured at 75.7 dBA (a 19.4 dBA reduction).

Reciprocating Compressors

The Problem:

(2) Large reciprocating compressors create unwanted noise

Solution

Noise-Tamer Alum-A-Frame modular enclosure system

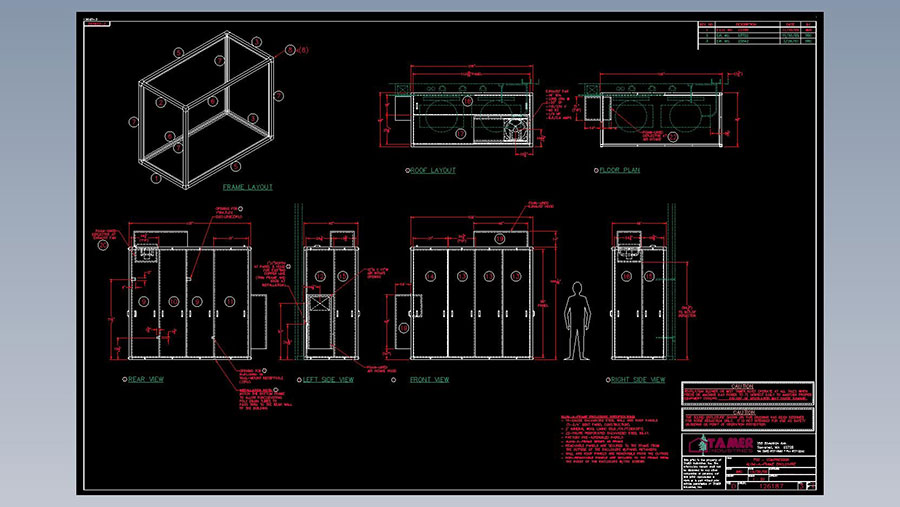

Enclosure Specifications

- Gauge galvanized steel wall and roof panels

- 2”-6#/cu.ft. mineral wool (bagged) lining

- With 22 gauge galvanized perforates steel inner surface

- Alum-A-Frame Series 24/50 frame with die-cast aluminum corner joints

and pre-cut aluminum extrusion-mill finish, 0.078 wall thickness

Overview of Benefits

- Substantial noise reduction

- Pre-engineered design

- Easy access through removable panels

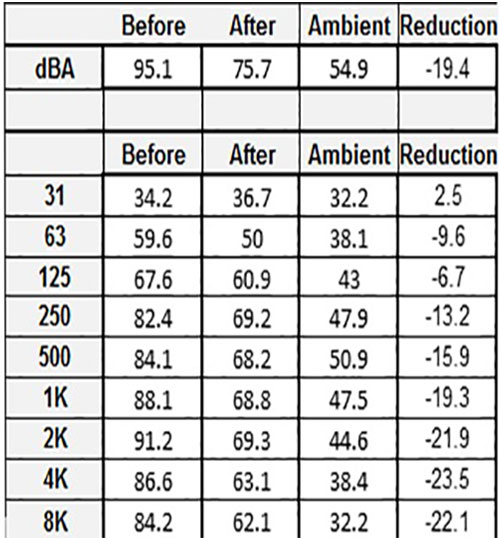

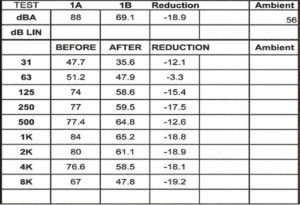

Results – Evaluation

Sound pressure levels were taken approximately 3 feet away from the noise source. The starting noise level was measured at 88 dBA. Upon completion of the Noise-Tamer Alum-A-Frame enclosure,

the reciprocating compressor noise was reduced to 69.1 dBA (an 18.9 dBA reduction)

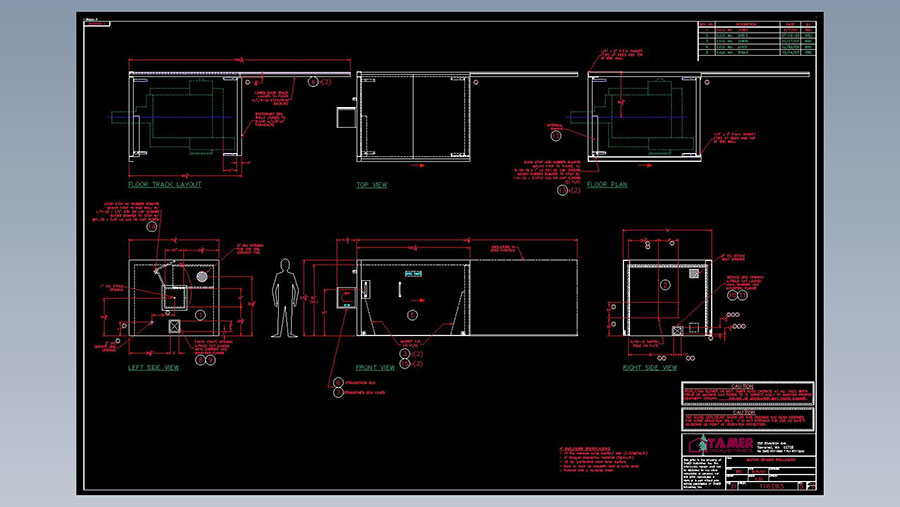

Wafios Nail Header

The Problem

- Excessive noise

- Limited floor space

Solution

Custom Noise-Tamer floor saver enclosure. Floor saver enclosures have inside dimensions as little as 1” from the extents of the machines being enclosed saving valuable floor space. Large doors or rolling tunnels are usually provided to allow access to the entire machine.

Enclosure Specifications

- 14 GA. Damped outer barrier/skin (3.125#sq.ft.)

- 4″ bagged absorption material (6#/cu.ft.)

- 22 GA. Perforated steel inner surface

- Acoustic seals on both door ends

Overview of benefits

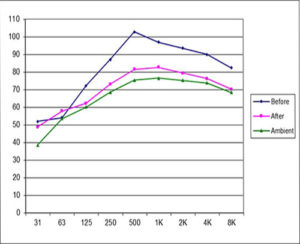

- Noise reduction (see before and after readings)

- Inverted “U” shaped rolling tunnel providing access to 2-sides and top

- Powered ventilator keeps the machine cool

Results – Evaluation

The starting noise level was measured at 105.4 dBA. Upon completion of the Noise-Tamer enclosure, an ambient reading was measured at 82.1 dBA. With the enclosed Nail Header operating the measured reading was 88.2 dBA. The high ambient level of 82.1 has influenced the readings taken after the installation of the enclosure. To determine the actual effectiveness of the enclosure additional readings should be taken when ambient levels can be reduced to a minimum of 20 dBA below the operating machine levels so as not to impact the enclosed machine readings.

Reduce noise and gain a cleaner,

quieter, safer working environment…

If necessary, Tamer can perform on-site acoustic readings to determine the

frequency profile of your application. With this we will determine the best

treatment method and materials to control your noise problem.

Most enclosures utilize our standard 2” or 4” thick modular panels but we don’t stop there. Our ability to customize your enclosure to meet the specific needs of your application means you receive an engineered solution that not only achieves the required noise reduction, its conducive to daily operation and machine maintenance.